Quick-Release Hydrofoil Bolt

2022

Client

Leves

Project Overview

Leves set out to test a common frustration in surf hydrofoiling: the slow and fiddly process of attaching a foil mast to a board using the standard sliding track system. Traditionally, this involves aligning the mast and securing it with four T-nuts and a handheld tool — not ideal on a windy beach or in shifting sand. The challenge was to create a fast, tool-free solution that worked seamlessly with the existing sliding track format. The final design featured a quick-release bolt that could be hand-tightened and locked down with a lever, allowing for easy adjustments both on and off the water. The product was built using a combination of turned parts and a basic extrusion for the lever.

My Role

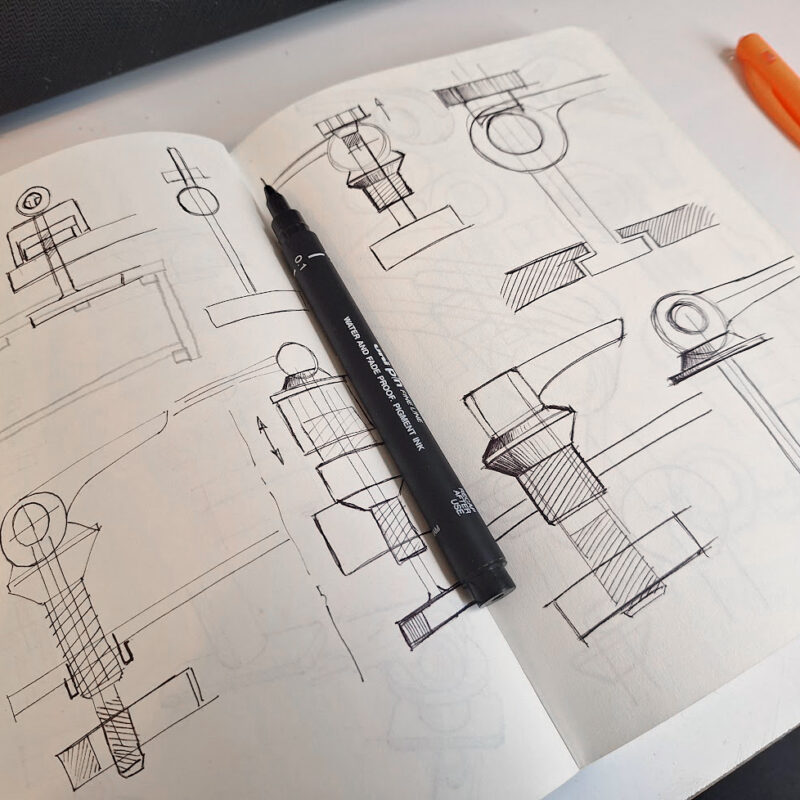

Starting with napkin sketches, the idea was fleshed out to a point where I was able to jump into CAD modelling to explore mechanical layouts, tolerances, and assembly strategy. Early concepts were prototyped using in-house FDM 3D printing and later higher quality SLA prints to validate fit and usability. Once finalised, parts were manufactured offshore using CNC-machined stainless steel and anodized aluminium. Close collaboration with the factory was essential to ensure press-fit tolerances were met and visual finishes — including anodising and laser engraving — were delivered to spec.